roughing end mill diagram

End mill A multi-functional tool which has cutting edges on the periphery and an end face. Figure 11 shows surface temperature variation of the work-rolls in the roughing mill where they are cooled using two water sprays with convection heat transfer coefficient of 30 000 W m 2 K 1 and heat transfer coefficient for the film cooling region is taken as 6000 W m 2 K 1.

Roughing End Mill Kyocera Unimerco

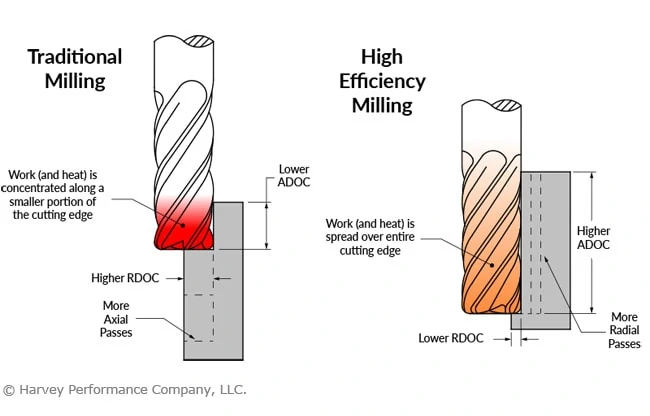

HEM is a roughing technique that uses a lower Radial Depth of Cut RDOC and a higher Axial Depth of Cut ADOC.

. Ball nose cutters or ball end mills lower row in image are similar to slot drills but the end of the cutters are hemispherical. While end mills have traditionally had. The tooth design allows for little to no vibration but leaves a rougher finish.

Length of Cut LOC. The rolling parameters were adopted from the No. End Mills cut rotationally in a horizontal or lateral side to side direction whereas a drill bit only cuts straight down vertically into the material.

Roughing end mill diagram Saturday July 30 2022 Edit. Using Traditional Roughing. Roughing and Finishing Capabilities.

Shell Mill Tool Holders. Milling cutter A rotary cutting tool having many cutting edges on the periphery or an end face of a cylinder and a cone. The fine-pitch end mills leave a better finish and dont require as much stock to be left to clean up with a finish pass using standard end mill.

Normally a 20 reduction in effective horsepower is used. Roughing end mill Rough-cutters have notches or serrations on the cutting edge which like a mechanical shredder produces shorter easier-to-manage chips. Floating Tap Tool Holders.

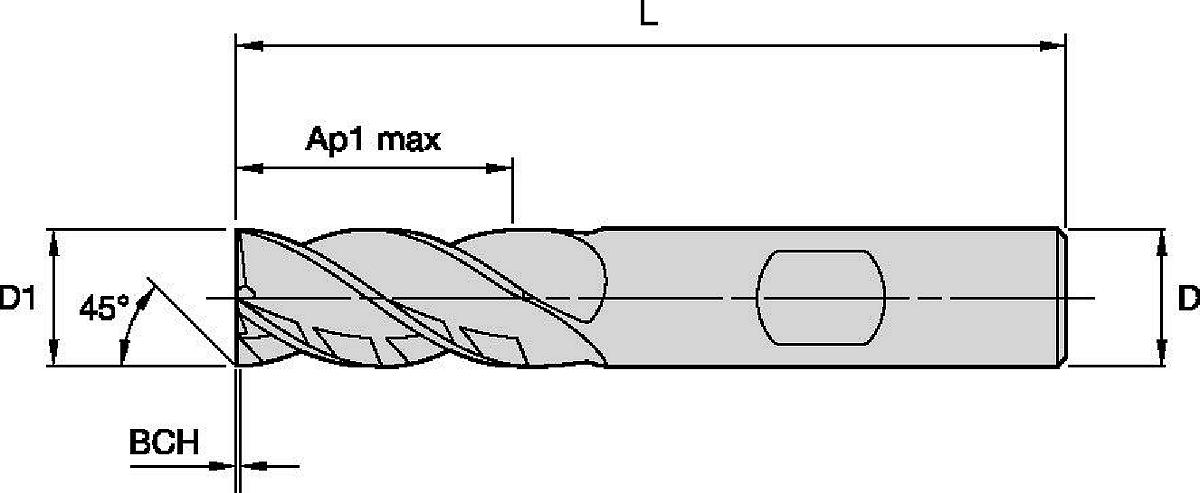

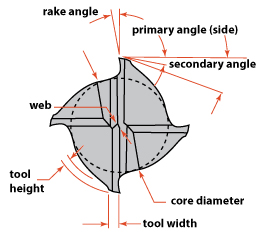

The SSDH series achieves superior chip flow and evacuation through the introduction of chip-release flute form technology and a unique inter-flute helical transition all within a patent pending design. End mill cutter geometry. End Mill Definitions.

Available in Stub Standard Medium and Reduced Neck. The SS series is offered in stub standard. Corner radius end mills have a rounded cutting edge and are used where a specific radius size is required.

Over 400k Businesses Trust Zoro. A premium rupture resistant substrate is the foundation to. Made of solid carbide these end mills are harder stronger and more wear resistant than high-speed steel and cobalt steel.

The SS series 3 flute end mill remains the work horse when roughing in ferrous alloy applications. Roughing end mills also known as hog mills are used to quickly remove large amounts of material during heavier operations. Back Aluminum Cutting Endmills Roughing End Mills Fractional Square End Mills Fractional Ball End Mills Double End Stub End Mills Long Cut Square End Mills Long Cut Ball End Mills Extended Reach End Mills Corner Radius.

Ad Inch and Metric Mills - Single or Double End Roughing Mini Long Ball End. This spreads wear evenly across the cutting edge dissipates heat and reduces. Taper Adapter.

It is possibler to gash a rougher on a tool cutter grinder or even a pedestal grinder with a hand-formed saucer. Ad Manufactured By Industry Leaders. End Mill Tool Holders.

Tool Holder Collet Nut. Roughing End Mills for Aluminium Roughing End Mills for Al-alloy High speed milling over 6000ccmin ded. Milling Chuck Tool Holders.

Roughing end mills also known as hog mills are used to quickly remove large amounts of material during heavier operations. Tool Holder Tightening Fixture. Shrink Fit Tool Holders.

A ball end mill is constructed of a round cutting edge and used in the machining of dies and molds. 3 Micron Runout at bore. A standard corner radius protects the tool corner and enhances tool life in aggressive roughing applications.

Roughers are one of the hardest tools to get right on a tool cutter grinder as the inside of the flute the top face has to be ground where-as a conventional end mill is sharpened by grinding the outside of the cutter. While traditional roughing is occasionally necessary or optimal it is generally inferior to High Efficiency Milling HEM. Sign in to download full-size image.

Design that Virtually Eliminates Flute Packing and Obstruction. For Taps Dies Cutting and Measuring Tools. Up to 16 cash back Ball end mills also known as ball nose end mills are used for milling contoured surfaces slotting and pocketing.

Corner chamfer end mills have an angled cutting edge and are used. Floating Tap Tool Holders. Cutting Edge Tooth The sharp edge of the end mill tooth Flute The deep spiral grooves behind each cutting edge that allow for chip formation and evacuation.

Carbide Square End Mills. 38 Dia x 1-14 Cut 3FL Aluma-Rough. 2 roughing mill in CSC and are summarized in.

1 C-SRA C-MRA C-SRARB 616mm 25mm 655 Õ 5 10 30 50 70 1000 2000 3000 4000 5000 6000 Roughing End Mills for Aluminium Wide variation Highly efficient Roughing. 1High quality material of carbide2Wear-resisting and Not easy to stick milling cutter3High efficiency of chip removal4Speed machining and High degree of. 40 35 63 mm.

Screw-In Threaded Body Tool Holder. Drill A tool for drilling. Side milling curved surface milling and drilling are possible only by one.

Up to 16 cash back 1 Diam Fine Pitch 2 LOC 5 Flute Cobalt Roughing Square End Mill TiAlN Finish 4-12 OAL 1 Shank Diam Single End Centercutting 30 Helix MSC 84512763 Hertel 84512771 In Stock. Roughing End Mills for Aluminium Roughing End Mills for Al-alloy High speed milling over 6000ccmin ded. Cutting edges are only on a top.

Haas roughing end mills come in fine- and coarse-pitch versions. Made of solid carbide these end mills are harder stronger and more wear resistant than high-speed steel and cobalt steel for the longest life and best finish on hard material. 38 Dia x 1 Cut 3FL Aluma-Rough Carbide End Mill For Aluminum USA F22.

Heavy cuts can be achieved because our roughing end mills have a much higher effective feed per tooth than a conventional end mill. Regal Cutting Tools manufactures a variety of roughers for a wide range of materials and conditions. Fine-pitch scallops are smaller and better for lighter cuts in hard materials.

The dimensions of the components are listed in Table 1. Hpmt Sc Roughing Endmill G6110 Kyocera Unimerco. Endmills are available in a wide variety of lengths diameters flutes and types and are chosen according to the material they are cutting and the surface finish required for the project.

Their extreme hardness means they are brittle so a highly rigid setup such as a CNC machine is necessary to prevent the end mill from. End mills do not have cutting teeth across all of the end but have a dead area in the centre and thus can only be used for milling using the side of the cutter and the outer periphery of the ending end Figure 1133. Deep slotting or deep profile applications with a lot.

Ad Buy Cutting holemaking shaping tools. Roughers have chip-breaker cutting edges the peaks on each cutting. Cutting Diameter The size measured as a straight line across the center of a theoretical circle formed by the cutting edges as the end mill rotates.

Large temperature variations occur at the surface region of the work-roll owing to severe temperature.

Roughing End Mills रफ ग ए ड म ल In Midc Bhosari Pune Orient Tools Id 3666888530

End Milling An Overview Sciencedirect Topics

End Mills Cad Cam Engineering Worldwide

8 Ways You Re Killing Your End Mill In The Loupe

Carbide Square End Mill 4 Flute 2d Flute Length Short Model Misumi Misumi

Basic End Mills Technical Information Msc Industrial Supply Co

Hpmt Sc Roughing Endmill G6110 Kyocera Unimerco

End Mill An Overview Sciencedirect Topics

End Mill An Overview Sciencedirect Topics

Schematic Diagram Of The Side Milling Process Download Scientific Diagram

Roughing Chip Breaker Bits 4 Flute F4zc45 End Mills Drills Frezycnc Eu

End Mills For Carbon Steel 4 Flute End Mills Drills Frezycnc Eu

Solid Carbide End Milling Harvi I Te Four Flute End Mill For Roughing And Finishing Covering The Broadest Range Of Applications And Materials

The Secret Mechanics Of High Feed End Mills In The Loupe

Basic End Mills Technical Information Msc Industrial Supply Co

Endmill Design Basics Mastercut Tool Corp

End Milling An Overview Sciencedirect Topics

Geometrical Parameters Of End Mills For Roughing And Finishing Part Download Scientific Diagram